DLN offers complete system audits of your existing operation, equipment, and processes; and then will generate a detailed document with specific recommendations for how to optimize the performance and efficiency of your warehouse and operations.

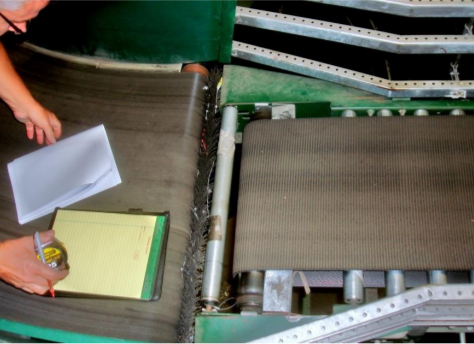

Preventative Maintenance (PM) Inspections can extend equipment life, reduce downtime, increase operator safety, and increase system performance. Our reports will identify current conditions, faulty areas, potential bottlenecks, breakdowns, and safety hazards.

Methodical Review

The DLN team reviews the details within the big picture of the system. Working down a list, these major areas are analyzed:

- Mechanical Systems – conveyors and loading

- Controls Systems – safety controls, connections to WCS, WMS

- Sortation Systems – accumulation, gapping, scanning

- Overall Operational Efficiency – picking, putting, automation

- Energy Management – electrical, mechanical, automation

- Planning for Growth – plan, do, check, act

Small Changes Lead to Big Differences

The goal of the system audit is to provide a snapshot of where you are now and how to make immediate improvements for measurable results. The goal is not to set the stage for a conversation about changing everything.

We audit your operation in an effort to get as much potential out of the existing system as possible. We provide unbiased guidance about what actions to take now by prioritizing improvements and alterations.