Robotics Ease Heavy Task

Client:

Conagra

Industry:

Food & Beverage

Solution:

Robotics & Automation

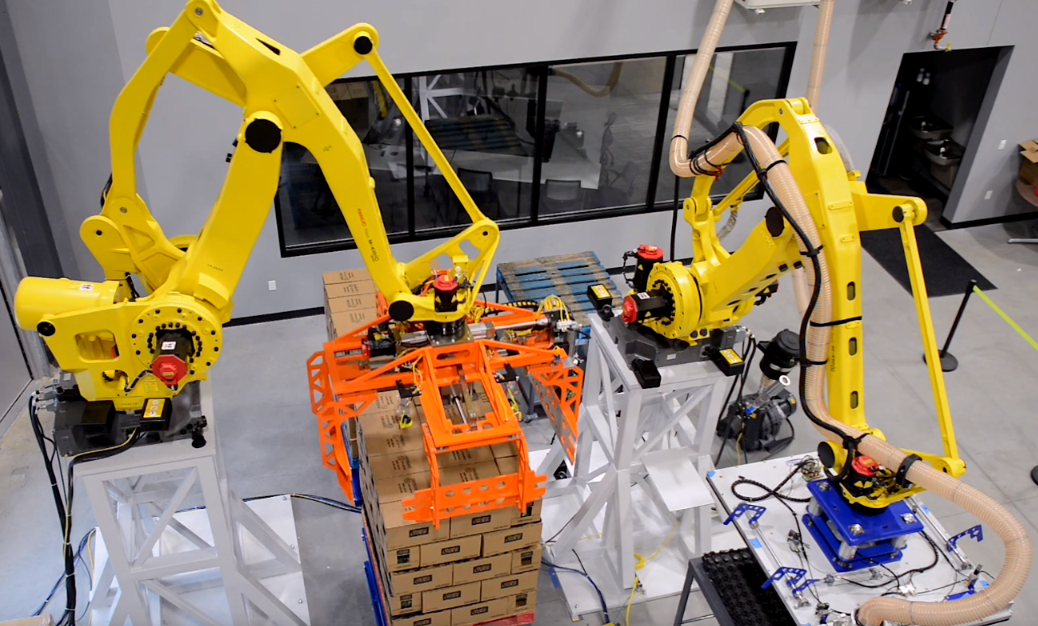

Conagra is a consumer packaged goods company with $11.B revenue and 18,000 facilities seeking creative solutions to improve efficiency.

Challenge

- Multi-temperature handling environment required equipment that could operate in varying temperatures

- Food packages were prepared using slats between each layer of product for optimum flash freezing

- The slats then created the need to handle each layer of product twice – to remove the slat and then to prepare for shipping, creating a heavy manual task

Solution

- DLN implemented 2 robotic cells with 2 arms each, working in tandem: 1 robotic arm with layer picking attachment to transfer product to new pallet & 1 robotic arm with gripper removed slats

- DLN replaced conveyeor, stretch wrappers, controls and upgraded safety equipment

- 2nd project underway for additional de-slatting cells with direct feed to automated truck loaders

Results

- Reduced headcount by 50% (4 per shift to 2)

- Increased throughput by 15%

- Decreased product damage by 40%