The Cost of Not Thinking Through Material Handling Investments

Part two of a two-part series.

See part one, covering WHY it’s more important than ever to analyze before investing.

How to Make the Best Investment Decisions?

A solution doesn’t need to be flashy or packed with the latest automation features to effectively meet the business needs.

Many distribution leaders have preconceived notions about which solutions they need, often based on solutions chosen in the past. But these assumptions may no longer be relevant amid the quickly changing landscape.

Getting the Early Steps Right

Conduct a feasibility analysis to validate the right course of action before entering a detailed design phase. This will help narrow down the budget range in which the business case makes sense.

Conduct a feasibility analysis to validate the right course of action before entering a detailed design phase. This will help narrow down the budget range in which the business case makes sense.

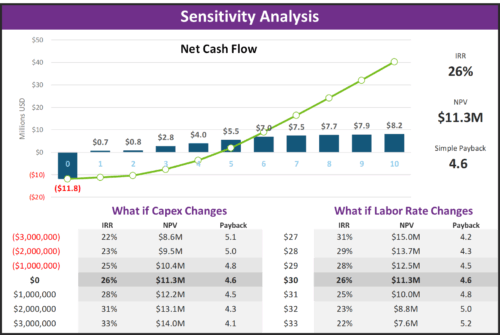

Stress Test Your Business Case

Confirm the business case holds up under a variety of different circumstances. The point is to discover what level of deviation would change decisions on the right course of action.

Input From Several Stakeholders

Designing a solution based on the input of a function-specific leader, such as a distribution center director, might limit understanding on the full benefits of an investment. Or even worse, it might skew the outcome due to only considering benefits inside the four walls, ignoring potential impacts in other parts of the business.

In contrast, communicating with different stakeholders will help to build a more complete justification and come up with the best strategic outcome for the business. This will help when presenting the business case to senior-level leaders that understand the full range of business needs because their responsibilities touch more parts of the operation.

Complete Due Diligence on Design

Avoid pulling the trigger on a project based only on ‘half-baked’ assumptions from a bidding process. After the partner has been selected, a proper design effort should be conducted to confirm assumptions, select the right solution and avoid budget and schedule overruns.

Automation Isn’t an All-Or-Nothing Prospect

Solutions targeting specific inefficiencies usually offer a much better cost/benefit ratio than fully automated systems. A company may like the idea of going with a highly modern approach that has reasonable ROI. However, there may be a less-automated alternative that offers 80% of benefits at only 40% of the cost.

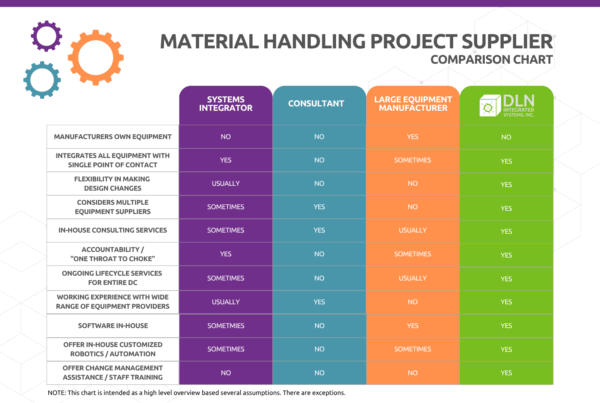

5 Important Considerations for Choosing The Right Partner

Choosing the right partner comes down to the fundamentals: people, track record, sound processes, technical skill and experience.

Selecting the optimal company for guidance isn’t easy, given the plethora of options in the marketplace. Let me relay five capabilities I consider highly important, based on my work helping dozens of companies plan and execute complicated supply chain projects:

Company Culture

Company Culture

Unfortunately, our industry often experiences high turnover, which erodes the quality and consistency of projects – especially when teams are staffed with inexperienced associates who may be replaced after just a few months. Choosing companies with strong values, a positive culture, long-tenured employees, and a solid track record can have a direct impact on the success of the project.

Familiarity with Industry & Project Type

Familiarity with Industry & Project Type

Each project is different and has unique requirements, but there are certain themes and technical characteristics commonly associated with specific industries or project types. For instance, if the goal is to retrofit an existing operation to extend a building’s lifespan, it’s best to choose a partner that has executed on such projects and knows the factors to anticipate and plan for.

Data-Driven Studies & Evaluation

Data-Driven Studies & Evaluation

A good partner should have the capabilities to conduct engineering studies that include steps ranging from comprehensive data analysis and hands-on site visits – to set the right parameters for sizing the solution – to agnostic evaluation of applicable technologies and the development of accurate solutions and investment estimates.

Applications Engineering

Applications Engineering

At the end of the day, the best solutions rely heavily on sound and accurate engineering skills. This means reducing complexity, enabling maintenance, increasing safety, optimizing people and product flows, and ultimately getting the most benefits out of the investment.

Real-World Experience

Real-World Experience

You can solve a problem using data science and understand all the technical specifications of the equipment, but the result isn’t always practical. That’s because there’s an art to the science. Too often, standard productivities or equipment rates are assumed, processes are over-engineered, or storage needs are underestimated. Without real-world experience, what seems like a gooda solution might lead to unintended consequences—such as added complexity, unnecessary steps, performance gaps, and reduced capacity.

A Trusted Partner

Working with a proven advisor in assessing challenges and solutions increases the chances of success.

DLN’s Supply Chain Consulting practice is more than just a technically experienced operation. It emphasizes a multi-functional approach, a positive company culture and a team of skilled consultants and engineers with decades of real-world experience.

We operate with a flat organization and a ‘hands-on’ leadership team that is very accessible to our clients. We are fortunate to have extremely low turnover, which is not typical in our industry. These are differentiators that can help drive success for a wide range of distribution clients in the material handling space. Feel free to reach out to start the conversation.

About the Author

About the Author

Ricardo Parra, Senior Director of Professional Services

With 30 years supply chain experience, Ricardo has led operation transformation initiatives to develop solutions for dozens of major brands, helping them design complex material handling systems, optimize their footprints, develop ecommerce capabilities, and insource/outsource logistics.

In his current role he combines in-depth analytics and broad business and operational acumen to conceptualize practical and effective solutions, he is well versed in developing business cases and interfacing with executive decision makers.