Part 3 of 3

This post is part 3 of 3, covering DLN’s educational conference Optimizing Supply Chain for What’s Next, held in May 2025.

See Post 1 of 3 covering consumer trends.

See Post 2 of 3 covering developing supply chain talent.

The final speaker of the day, Luke Nuber, DLN’s Director of Sales Operations, addressed how to keep your distribution center (DC) modernized—without breaking the bank.

The final speaker of the day, Luke Nuber, DLN’s Director of Sales Operations, addressed how to keep your distribution center (DC) modernized—without breaking the bank.

He explained that market conditions are constantly evolving, but most legacy DCs were never designed for today’s competitive pressures of speed, accuracy, assortment, and low-cost needs. Supply chain professionals instead deal with:

- Slow, long cycle times

- Human error

- Space constraints

- Inefficient, labor-intensive processes

The result? A widening gap between what your DC can do and what your internal and external customers expect.

Modernizing DC Operations for Competitive Advantage

Nuber said a new DC seems to be the only solution when faced with these issues. However, the trade-offs of a new build are clear:

- It’s tens of millions in capital.

- It’s disruptive. New builds mean significant transition risk, not only for operations, but across the supply chain.

- Increased inventory is required due to SKU duplication and safety stock at each node.

- Increased complexity often comes with more square footage, which adds the complexity of having to manage multiple inventories and decide the best place from which to ship each order.

So instead of waving a white flag, he suggested the audience consider modernizing their existing DC operations to today’s standards. This can provide the seamless delivery experience that their customers expect combined with the performance their investors need.

So instead of waving a white flag, he suggested the audience consider modernizing their existing DC operations to today’s standards. This can provide the seamless delivery experience that their customers expect combined with the performance their investors need.

“There’s a better path than just a shiny new building,” Nuber said.

That path includes first reviewing the best practices of optimization.

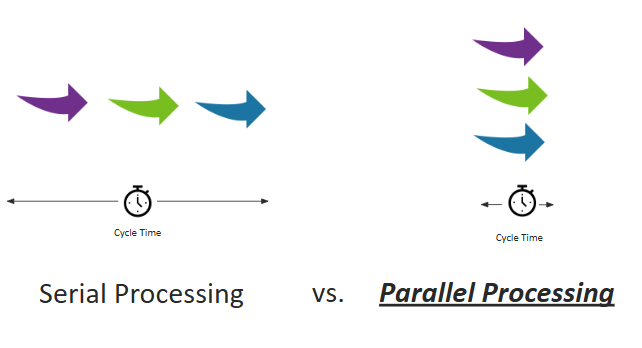

Nuber shared examples of speed, where focusing on cycle time can lead to goods-to-person or automated selection processes. Instead of discrete picking, a form of serial processing, he suggested supply chain leaders think about batch picking, a form of parallel processing.

“A lot of people working together at the same time reduces cycle time,” he said.

Whether it’s pick or put to lights to clearly indicate instructions, GUI screens that include visual item verification, or a single item presented to a picker, Nuber said applying new technology will improve the accuracy of a DC.

Final optimization best practices include using high density, high selectivity storage for assortment, targeting automation that is flexible and scalable for labor, and focusing on footprint because space is expensive.

“Look for these things as you’re considering modernization,” Nuber said.

Next, Nuber shifted to highlighting modernization strategies. He first acknowledged that if a company has greater than 10 percent sales growth, geographic expansion opportunities, access to capital, and 3+ years to wait, a new DC could be the right fit for them.

But he reiterated his earlier point that most supply chain leaders deal with:

- Capital constraints from competing priorities and the temporary high cost of capital.

- Customer demands that need capabilities yesterday.

- Good business sense that points to maximizing current assets.

Which means modernizing a legacy DC has a clear edge over new DCs, he said.

“That always wins the day if you are doing an honest financial comparison,” Nuber said.

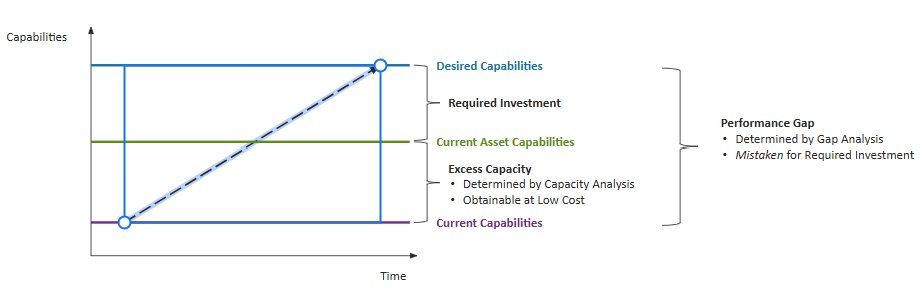

He encouraged attendees to start with a gap analysis and capacity analysis to identify capabilities in equipment they already have. Using excess capacity reduces investment and provides justification for projects.

Nuber stressed that the capacity analysis should be more than just the current rate. Supply chain leaders should ask questions like:

- How fast can a machine go?

- How could that rate be increased?

- How can uptime be increased?

- Can workers be added without congestion?

- Is there underutilized space in the building?

After conducting a maintenance audit as well, he recommended focusing on high efficiency equipment and processes.

Nuber shared a few examples of technology to consider for the modernization strategy:

- Pick modules. They reduce footprint and are a low-cost investment. Labor costs can increase though and downstream may be affected. Understand the full process and design for expansion.

- Shuttles/goods-to-person. They are highly productive and provide a good use of vertical space. Leaders must consider the machine rate manufacturers share is greater than human capability. Solicit an unbiased expert to help with the evaluation.

- Top-off buffers. Connects pick modules or shuttles to pick-to-pallet processes and increases selector productivity. Carefully design the operational flow to ensure flexibility without oversizing the buffer and consuming valuable space.

- 2D pallet shuttle. They have high storage density, are highly scalable, and provide improved uptime. Leaders should consider inventory profile, pallet quality, and peak throughput before investing. Ideal applications are often justifiable on space savings alone.

He finished his practical speech by comparing the modernization planning process to chess. Distribution leadership should expect difficulties. They must be ready for setup moves, ways to keep operations going while still making improvements. These can include:

He finished his practical speech by comparing the modernization planning process to chess. Distribution leadership should expect difficulties. They must be ready for setup moves, ways to keep operations going while still making improvements. These can include:

- Offsite storage

- Network volume shifts

- Temporary work areas

Nuber said big updates take time to develop, and assumptions can be wrong, so start the planning process early. Also be flexible, because the project will likely take longer and cost more than expected.

“You don’t want to rush (the modernization process),” he said.

Key Takeaways

After our final speaker of the day, we surveyed our attendees to create some key takeaways. According to their responses, we were all able to conclude the following:

![]() Our struggles are real, we’re not alone

Our struggles are real, we’re not alone

The thoughts and feelings from all levels of a company (from the frontline operators to the C-suite) aren’t as drastically different as one might expect.

![]() Empathy and communication for the win

Empathy and communication for the win

Empathy for people in different roles can make a big difference. And communication, good and bad, with stakeholders is key. In other words, soft skills are becoming more important than technical skills.

![]() Consumer behavior is changing rapidly

Consumer behavior is changing rapidly

“The speed and volatility of it all, we heard loads about how things like viral social media trends and what influencers are pushing, can just instantly change demand patterns, like overnight,” Shattuck said in her audio summary of the conference.

![]() Distribution centers must keep up

Distribution centers must keep up

Modernizing a warehouse is a viable option for buying more space and supply chain leaders need to lean on strategic partners without a bias to help make competitive decisions about them.

![]() AI supplementing work, not replacing it

AI supplementing work, not replacing it

Leveraging AI needs to become a normal part of work efforts to maximize results and reduce time.

Click for Part 1

Covering consumer trends related to supply chain!

Click for Part 2

Covering developing the next generation of supply chain talent!