Reviewing the Pros & Cons of Supply Chain Consultancies, Equipment Manufacturers and Systems Integrators

“It’s clear it’s time to expand our distribution capacity but our executives are nervous about downtime. We need a partner that can help us make the expansion less painful.”

“We’re growing our network and my team does not have the experience to determine where we need to build a new facility – not to mention how to size or design it.”

“We have some older facilities we need to update but are limited by budget. How do we determine how to best spend our upgrade dollars?”

These are common scenarios for distribution and supply chain leaders. Identifying the issue and preparing to take action is the first step. Determining the ideal partner to help execute the improvements is the next hurdle.

We’ll cover, in a general way, three common types of companies that specialize in distribution center design & integration, which may include expanding or modernizing an existing facility or designing and building a new facility.

How to Decide the Best Partner for DC Design & Integration Projects

The three most common resources any one of these leaders can turn to are a consultant, an equipment manufacturer and a systems integrator. We’ll describe the role of each, plus some pros and cons.

The Role of Supply Chain Consultancies

Consultants carefully review an organization’s data and goals to create supply chain strategies and facility designs. They then send out bid packages for those designs and recommend the best providers to install and commission the equipment.

Consultants may stay involved throughout the project as an additional advocate for the overall strategy and to help manage the implementation of the system. Consultants do not manufacture or integrate equipment, but they maintain relationships with manufacturers and integrators on behalf of their end-user clients.

Pros to Using A Consultant

- Focused on your overall distribution goals & needs

- Unbiased and agnostic to solutions and technologies

- Accumulated knowledge from many design projects promotes creativity

- Ability to compare multiple concepts fairly and help determine the optimal solution

- Comprehensive tools and internal expertise to create plans & strategies

- Can help solicit and evaluate bids from a wide range of equipment providers

Cons to Using A Consultant

- Limited control and ability to influence the manufacturers and/or integrators implementing the design

- Virtually zero accountability for performance of the system

- Do not directly install or maintain equipment

- Rely on the OEM for detailed knowledge of equipment capabilities and functionality

- Client must manage contracts and relationships with each individual supplier on the project

The Role of Equipment Manufacturers

Equipment manufacturers design and make the branded equipment they sell. While some focus strictly on manufacturing and rely on integrator partners to design and integrate systems using their equipment, we’ll focus here on larger manufacturers. These have flexible business models that allow them to layer on services to compete in a wider range of project structures:

- When a consultant produces the initial design, they can include system integration services to complete the project.

- They may also work directly with an end-user and provide a complete turn-key system, offering upfront design in addition to integration services.

Larger manufacturers offer the majority of equipment needed for automated distribution facilities, from receiving to storage to order selection to shipping. When providing integrated solutions, they utilize their own equipment wherever possible and source specialty components as required to provide a complete solution.

Pros to Using A Manufacturer

- Intimate knowledge of the equipment installed

- Direct control over the manufacturing and delivery of the equipment

- Typically have robust lifecycle service offerings including hotline support, spare parts and preventive maintenance

- Often offer free consulting services

- Can be very cost competitive by avoiding middle-man markups on the most expensive parts of the system

- The larger manufacturers typically have robust WES software packages to integrate and optimize their equipment

Cons to Using A Manufacturer

- Equipment selected will always be the manufacturer’s own product, even when other manufacturers have better pricing or technology for that component

- No ability to utilize alternative suppliers to mitigate manufacturing issues

- May lack the capability or willingness to integrate with older or newer parts of a system, leading to disconnected or poorly integrated sections of a DC

- Manufacturers with integration services tend to be large, bureaucratic companies lacking responsiveness and attention to individual projects

- Service very large customers, meaning small and medium-sized projects can be de-prioritized

- Due to large customer bases, support resources tend to lack hands-on skill and knowledge of installed systems

The Role of Systems Integrators

Systems integrators work with end-users to engineer, install and commission material handling systems ranging from standalone projects, such as upgrading sortation or order picking, to entire automated distribution facilities. As with manufacturers, there are a wide range of company types with varying capabilities within the integrator landscape.

Some integrators are dedicated distributors of certain equipment brands, while others are independent and can source from a wide range of manufacturers based on what best meets the need of an end user. More advanced integrators, offer expanded services in areas like strategy, conceptual design, software, robotics and lifecycle services.

Some integrators have capabilities to integrate a broader array of systems within a DC, such as rack, AS/RS, AGV/AMRs and sortation systems, which helps simplify projects for end users. They manage the complex integration process with a dedicated project manager, providing a single point of contact for what may otherwise be 3-10 separate projects and suppliers for the end user to manage.

Pros to Using A Systems Integrator

- Single source of responsibility for a larger portion of projects; procuring, overseeing suppliers, installing and commissioning

- Are generally smaller companies (compared to manufacturers) that provide a more curated and responsive experience for end users

- Particularly when providing the upfront design consulting, integrators have the highest level of accountability for solution integration and performance, avoiding translation challenges of consultants and the finger-pointing and automation silos that can result from working with multiple manufacturers

- More capable integrators offer auxiliary services that provide a foundation for a strategic, holistic partnership supporting all distribution needs for their clients. These services can include in-house consulting, software, robotics and lifecycle services such as spare parts, maintenance training, system upgrades and even resident maintenance

- Typically, integrators have less overhead than large manufacturers, thus able to offer lower costs to clients

Cons to Using A Systems Integrator

- Not all integrators are created equally, so it’s important to ensure they have the experience and expertise needed for your project

- Integrators buy and re-sell the majority of the system, so the upfront cost might be higher versus purchasing direct from manufacturers. However, integrators typically get reseller discounts, allowing them to be cost competitive, and some have the ability to drive prices down by competitively comparing multiple manufacturers

- Integrators that don’t do the upfront design consulting will only be accountable to certain speeds and rates and may struggle to deliver the intended results

- Integrators can vary widely in software capabilities. Those using 3rd party software are highly reliant on the software provider, while others have in-house software that carries significant limitations

- Some integrators are weak on support and lifecycle services capabilities, lacking critical services like 24/7 hotline support, resident maintenance, proactive audits and upgrades or emergency on-site service

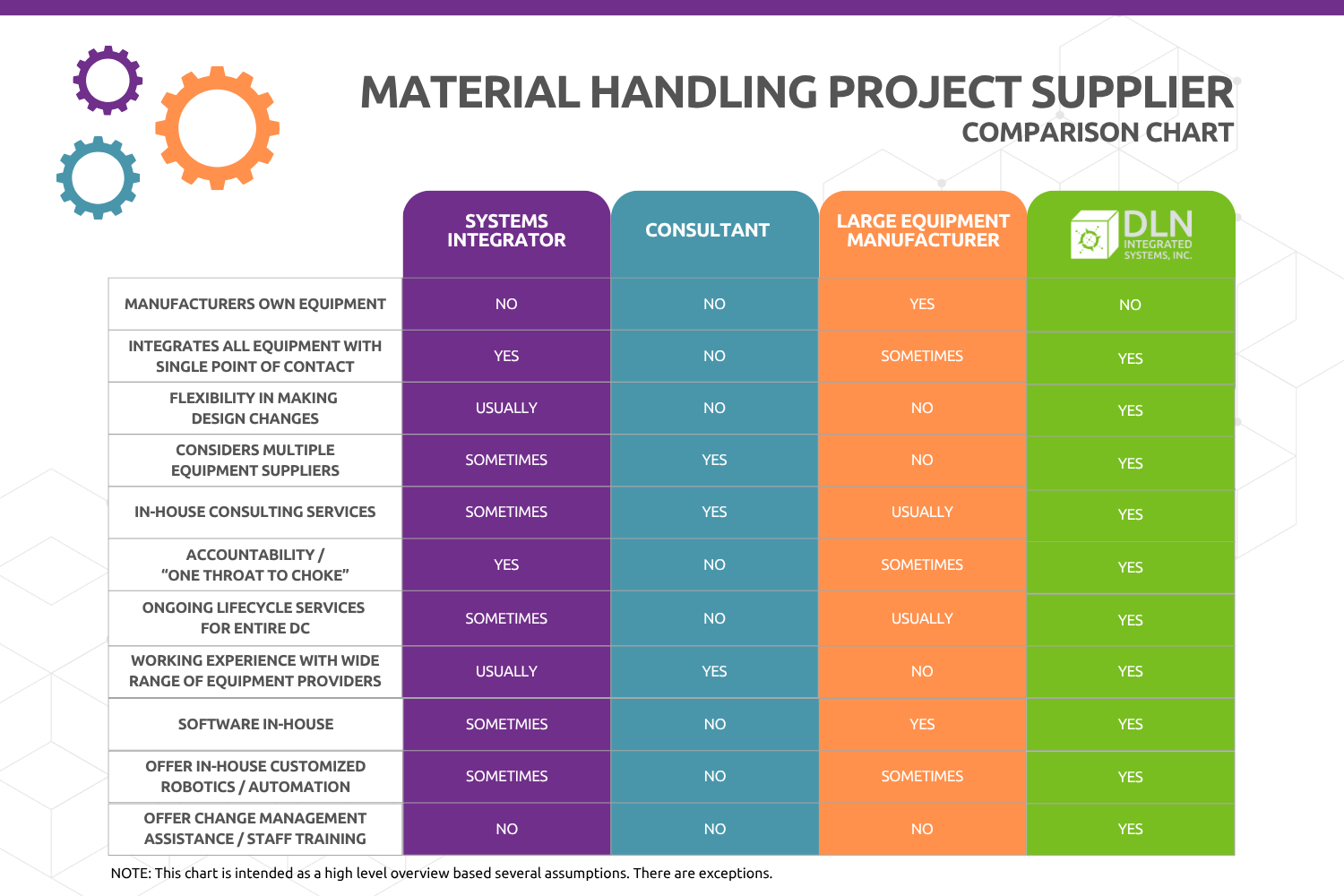

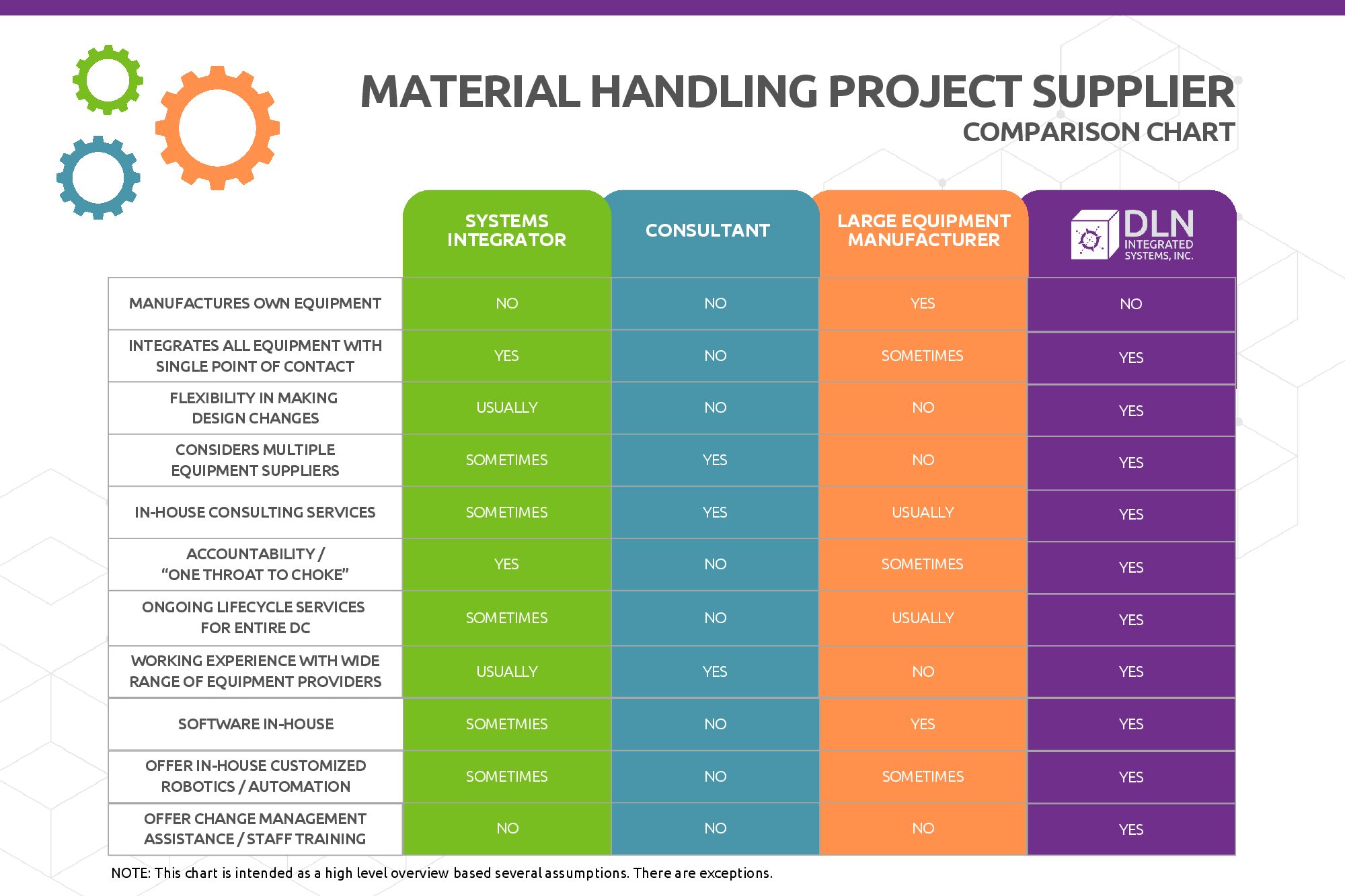

Comparison Chart – And How DLN Fits In

Conclusion

As you can see, there are many routes to follow to achieve an optimized facility that runs efficiently. Our goal was to highlight the pros & cons of using a Consultant, a Manufacturer and an Integrator. Every situation is unique and different, so you should consider what capabilities are important for your particular company and project.

The DLN Difference

DLN Integrated Systems is an integrator with a robust in-house consulting practice, software, customized automation and robotics, and a knowledgeable lifecycle services team. We also focus on operational readiness and preparing client teams for new equipment and processes by offering extensive testing, training, and change management to minimize the learning curve and accelerate system ramp-up.

Our team is committed to providing the optimal solution to our clients. Feel free to contact us to start a no-obligation conversation about your specific situation.