Part 2 of 5

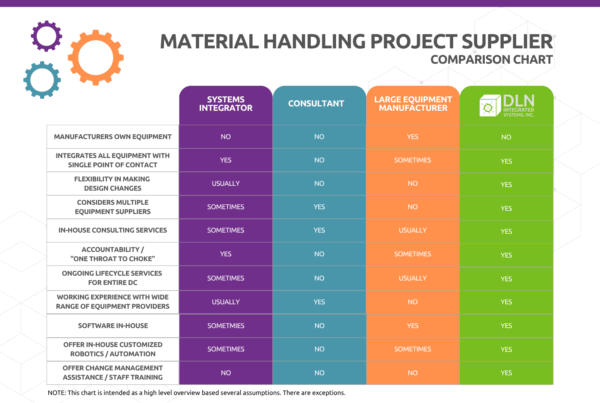

In the first installment of our five-part blog series, DLN and Connors Group outlined best practices for the first phase of the roadmap for successful distribution transformations – Conceptualization and Solutions Development – which can be found here.

In the Conceptualization phase, the distribution solution is defined at a high level. Design features like the size of the operation, processes and technologies to be used, as well as the project budget and implementation schedule have all begun to take shape. Ideally, the project has also been given an initial review and approval by the executive team and additional capital has been released to move forward. In other words, the project is now “real”, and it is time to shift into execution mode and start taking concrete steps towards bringing the concepted design into production.

In the Conceptualization phase, the distribution solution is defined at a high level. Design features like the size of the operation, processes and technologies to be used, as well as the project budget and implementation schedule have all begun to take shape. Ideally, the project has also been given an initial review and approval by the executive team and additional capital has been released to move forward. In other words, the project is now “real”, and it is time to shift into execution mode and start taking concrete steps towards bringing the concepted design into production.

Phase 2 of the process is Pre-Implementation, which can be further broken down into two related activities; Detailed Design and Program Planning.

In this second installment of our five-part series, we will expand our roadmap to successful transformation by taking a deeper dive into best practices for Pre-Implementation, again highlighting common pitfalls to avoid along the way.

Phase 2 – Pre-Implementation pt. A – Detailed Design

As you will recall from the first installment of this blog, the Conceptualization Phase is intentionally high-level.

It allows a small, nimble design team to efficiently review a number of process and technology options to identify the ideal design in a short period of time. While this is critical step in the process, it is important to understand that it does NOT produce a design that is ready to be implemented in your DC.

Today’s distribution operations are highly complex and most have a long list of exception processes and special requirements that the finished system needs to handle efficiently. While addressing each of these requirements in the Conceptualization Phase will grind it to a halt, it is equally dangerous to gloss over them entirely, as each will become a potential landmine at go-live.

Pro Tip:

While not exactly measuring, the old adage “measure twice, cut once” applies to the distribution design process as well. While it can be tempting to fast-track projects by placing orders based on conceptual designs, a “figure it out in the field” approach can have extreme impacts to the cost of expensive assets like equipment, programming, and productivity of a full DC. Invest wisely in a “measured” approach and don’t cut corners with upfront design.

While not exactly measuring, the old adage “measure twice, cut once” applies to the distribution design process as well. While it can be tempting to fast-track projects by placing orders based on conceptual designs, a “figure it out in the field” approach can have extreme impacts to the cost of expensive assets like equipment, programming, and productivity of a full DC. Invest wisely in a “measured” approach and don’t cut corners with upfront design.

Detailed Design is an additional review and refinement of all aspects of the solution in much greater detail and including a wider range of stakeholders.

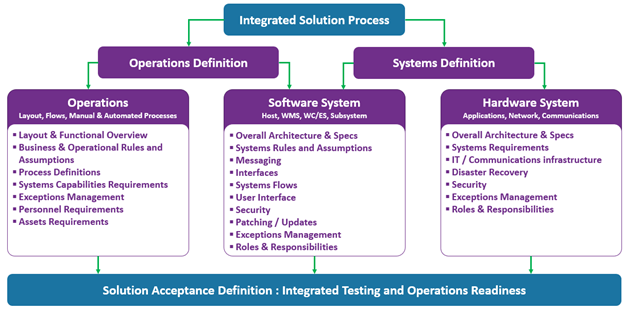

The ultimate outcome of the Detailed Design is an Operations Definition of the system, composed of a detailed accounting of the operational aspects of the system as well as the software functionality required to support the operations, and a Systems Definition of the system, composed of the software functionality and the hardware required to support it.

Detailed Design should be carried out by a cross-functional team of front-line leaders and SMEs from Operations, IT, any involved software, and material handling design.

The team should focus on one functional area at a time, reviewing and documenting all aspects of the process, and updating the layout, equipment, and systems functionalities so they are designed to fully support the operational requirements.

Pro Tip:

Plan for Exceptions Early

A common mistake is to focus Detailed Design efforts on only the process that each functional area should follow normally. While we hope to stay on this so-called “Happy Path” as much as possible, exceptions are bound to occur.

A common mistake is to focus Detailed Design efforts on only the process that each functional area should follow normally. While we hope to stay on this so-called “Happy Path” as much as possible, exceptions are bound to occur.

During Detailed Design, brainstorm as many possible exceptions as you can think of and design the process to handle them. Some may need to be handled manually and/or separately from the primary process flow if volume and frequency are low or the cost to run it though automation is high. Either way, Detailed Design is a great time to evaluate and decide the best way to handle each case.

This up-front planning will allow you to modify MHE and Systems to handle exceptions at a much lower cost and sets you up for a smoother go-live.

Before leaving the Detailed Design phase, be sure to also develop your testing plans for each functional area. Good testing plans will confirm that the operational process, systems, and equipment deliver the necessary functionality to support the business requirements for both normal and exception processes.

Therefore, Detailed Design is the ideal time to define testing plans while the requirements and functionality of the system are top-of-mind.

Pro Tip:

Test 3 Ways

Over-simplistic testing can leave potential issues lurking until after go-live, making corrections much more costly. Develop robust test plans that include (at least) the following 3 test types:

Over-simplistic testing can leave potential issues lurking until after go-live, making corrections much more costly. Develop robust test plans that include (at least) the following 3 test types:

- Subsystem Testing – initial test of intended functions for each subsystem (i.e. conveyors, WMS, etc.).

- Rate Testing – simulate peak day rates through each subsystem verifying they deliver the intended throughput and to uncover issues that only occur at higher volumes.

- Integrated Testing – test the full system with all subsystems online and working together through ‘day in the life’ scenarios that run through all steps of both normal and exception processes.

Phase 2 – Pre-Implementation pt. B – Program Planning

The other major piece of a successful Pre-Implementation is to plan the overall Program Structure and Process. Loosely defined, the ‘Program’ is the collection of all people, processes, systems, and equipment that will be impacted, directly or indirectly, by the transformational project at hand.

It includes both the external and internal project teams that will be responsible for carrying out various aspects of the project and associates at all levels of the company undergoing the transformation.

It includes both the external and internal project teams that will be responsible for carrying out various aspects of the project and associates at all levels of the company undergoing the transformation.

Therefore, Program Planning is the process of establishing the Program teams, processes and schedules that will support and guide the Program through completion. Setting up the Program Plan is best started during, or immediately following, the Detailed Design phase.

The first step of Program planning is typically to develop the Program Organization Chart, which outlines the individuals that will have some role in delivering the Program. This should be done broadly, including not just the primary project teams, but a wide spectrum of all company departments impacted by the change (e.g., HR, Procurement, IT, Transportation, etc.). A RACI chart is a great tool to use while developing the Program Org Chart. RACI stands for Responsible, Accountable, Consulted and Informed and defines the appropriate individuals and level of communication and involvement for each project task.

Using a RACI chart will keep the Program Organization appropriately informed without drowning individuals with unnecessary communication.

Pro Tip:

Involve EVERYONE (In the Right Way)

It can be tempting to build a very lean Program Org Chart comprised of a few knowledgeable ‘generalists’ that speak for the rest of the company.

While this can streamline planning and decision making, it risks a difficult go-live by missing critical planning inputs or having parts of the company unprepared.

Instead, engage ALL company stakeholders early in the process and develop a strategy that keeps everyone involved and informed in ways that are commensurate with their role in the change.

With the Program Org Chart and RACI in hand and Program resources identified and engaged, there are two more governing documents to get established during Pre-Implementation; the Program Schedule and the Program Updates.

With the Program Org Chart and RACI in hand and Program resources identified and engaged, there are two more governing documents to get established during Pre-Implementation; the Program Schedule and the Program Updates.

The Program Schedule is a master schedule maintained by the Program Managers that pulls in the individual project schedules of all the various teams involved with the Program and is used to coordinate activities and track overall progress.

Program Managers should also lead a Program Update meeting on a regular cadence (usually weekly) and distribute the critical notes from the meeting to all parties as defined by the RACI. Both are “living” documents that are continually updated and managed throughout the course of the Program and are critical to identifying and making needed course corrections throughout the Program.

Lastly, Pre-Implementation is an ideal time to engage the early stages of a number of activities that will be critical during the later stages of the transformation. These are often categorized as “Operational Readiness” or “Change Management” activities and are designed to prepare all parts of the Program Organization for the eventual go-live of the transformation.

While the following do not need to be completed in the Pre-Implementation stage, it is good practice to start them here so they can be managed and tracked by the Program Schedule and so they have plenty of time to be developed:

- Training

- Develop training guides for all future state job functions and processes, which range from minor updates to existing roles or completely new roles within the operation.

- Conduct Operations and Associate training. As appropriate, conduct testing of training materials and make sure associates achieve any appropriate certifications.

- Go-Live Preparation

- Create a Go/No-Go checklist for determining operational readiness.

- Physically set up and prepare a ‘War Room’ for Operations leaders during go-live.

- Determine the War Room schedule and staffing during the go-live period.

- Brainstorm possibly go-live scenarios and develop contingency plans for each.

Ultimately, the Pre-Implementation phase is all about planning and preparation.

phase is all about planning and preparation.

It is the most difficult phase to execute well because the temptation is to rush ahead to Implementation and “figure out the details later”.

Solid Pre-Implementation requires discipline and effort to complete thoroughly, but that effort is effectively planting the seeds for go-live in the future. Investments in quality Pre-Implementation will pay handsomely in the form of a smooth and successful go-live, making the Program Team leaders look like the seasoned professionals they are!

About the Authors

Luke Nuber

DLN Integrated Systems

Andy Hunter

Connors Group